Special Custom Made Screws

SPECIAL CUSTOM MADE SCREWS – This is our specialty

Custom Made Screws can be made to suit an application or product

It may be Dimensional

-

Head Diameter made smaller to fit in a specific space

-

Head Diameter increased for greater under head contact

-

Head Height reduced to give a low profile

-

Length made to suit applications where length is critical

-

Thread Diameters may need to be adjusted slightly, particularly in Self Tapping applications

It may be the Recess

-

Product being exported may require a Phillips recess, not Pozidriv (NZ Standard)

-

To prevent people easily dismantling a Product, like electrical,Security Recess required

-

Really positive Driving recess needed such as Squaredriv

It may be to Enhance a Product

-

Head shape altered to suit; say a Raised Countersunk Head

-

Head Marked with Customers name or initials

-

More decorative, or unusual, Recess’s such as 6-Lobe (Torx)

Other Combinations

-

Unusual combinations of Head, Thread, Recess

-

Apply a “Shank Slot” to a Thread to give cutting action during insertion

-

Unusual design of Solid Rivet

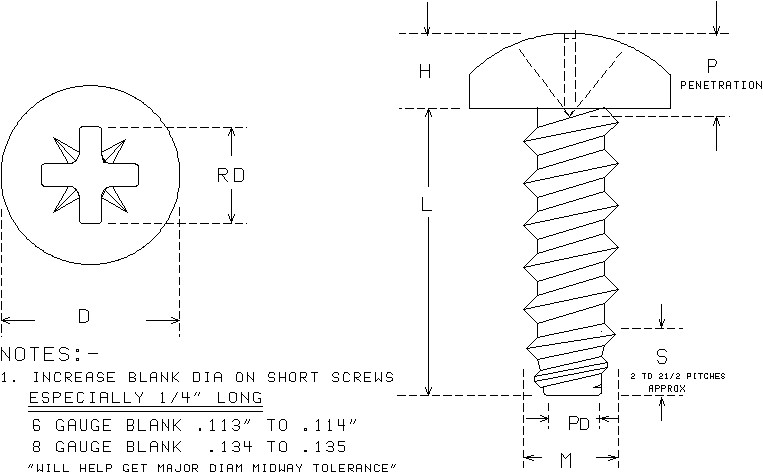

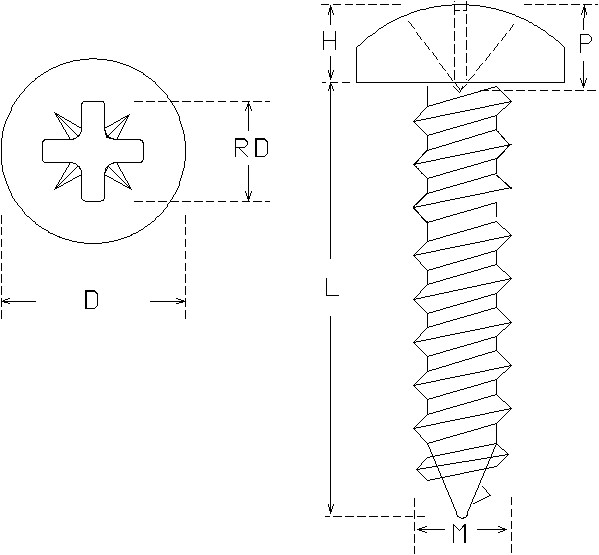

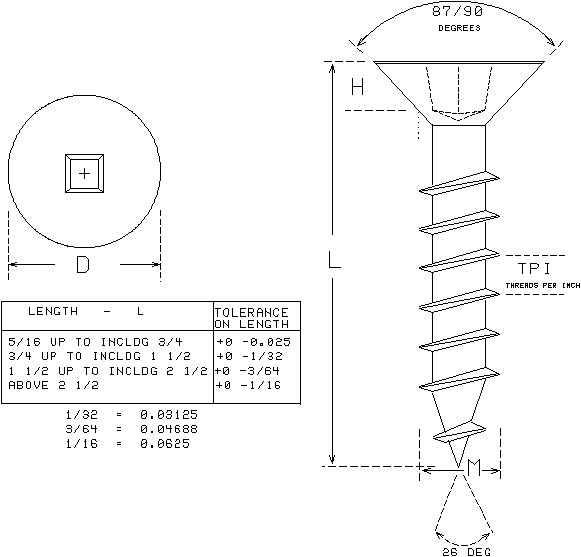

BELOW ARE JUST A FEW EXAMPLES OF SCREWS WHICH MAY ASSIST IN THE DEVELOPMENT OF A SPECIAL SCREW. PARTS FROM THE DRAWINGS BELOW CAN BE PUT TOGETHER TO DESIGN THE SCREW REQUIRED. THESE ARE NOT THE ONLY EXAMPLES AVAILABLE. THE COMBINATIONS AVAILABLE ARE VERY LARGE.

To begin the design of a Special Screw we require an idea of the following:-

Type or Shape or Head required; Pan, Round, Countersunk, Raised Csunk, Mushroom (Flange), Truss, Fillister, Wafer etc

-

Dimensions of that Head; both Head Diameter and Head Height

-

Type of Recess; Phillips, Pozidriv, Squaredriv, Trilobe (Torx), Slotted, Combination Recess's (eg Pozi/Slot, Phillips/Slot, Phillips Square etc), Slotted, Quadrex, Triwing, etc

-

Thread needed such as; Self Tapping (Type AB, Type B), Woodscrew(Twinfast, Hingefast), Machine Screw (Metric, BSW, Unified), Trilobe (Type S, Type P) etc

-

Secondary Operations; Shank slotting, Head Slotting etc

PAN POZI TYPE AB SELF TAPPER COUNTERSUNK SQUARE HINGEFAST WOODSCREW

PAN POZI TYPE B SELF TAPPER